| Navigation | GRAPHALLOY® Case Histories

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

LNG Pumps |  |

||||

|

Boiler Feed Pumps |  |

||||

|

Subsea Hose Reels |

|

||||

|

Green Energy |  |

||||

|

Slag Wool Production |  |

||||

|

Steel Application |  |

||||

|

Bakery Oven Doors |  |

||||

|

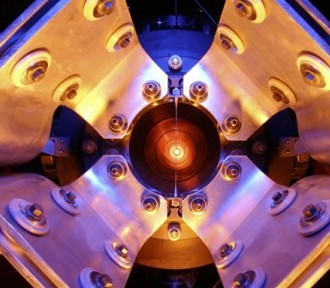

Fermilab |  |

||||

|

The Geysers |  |

||||

|

Geothermal Brine Pump |  |

||||

|

Stainless Steel Flange Block |

|

||||

|

|

|||||

|